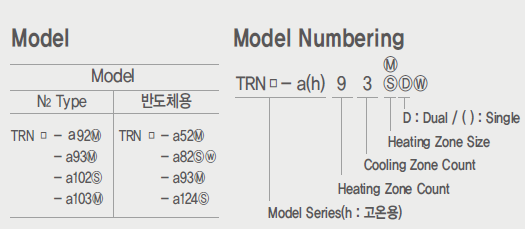

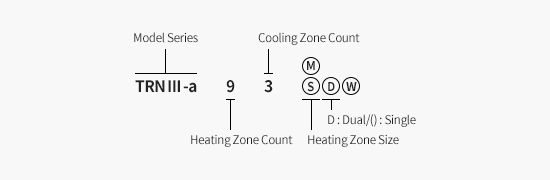

N2 Reflow(TRN III-a)

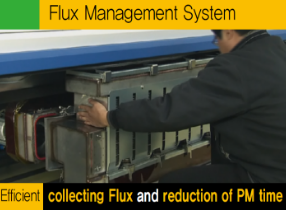

Consecutive six month operation (one year in max) without PM

N₂ REFLOW

TRN Ⅲ- a SERIES

-

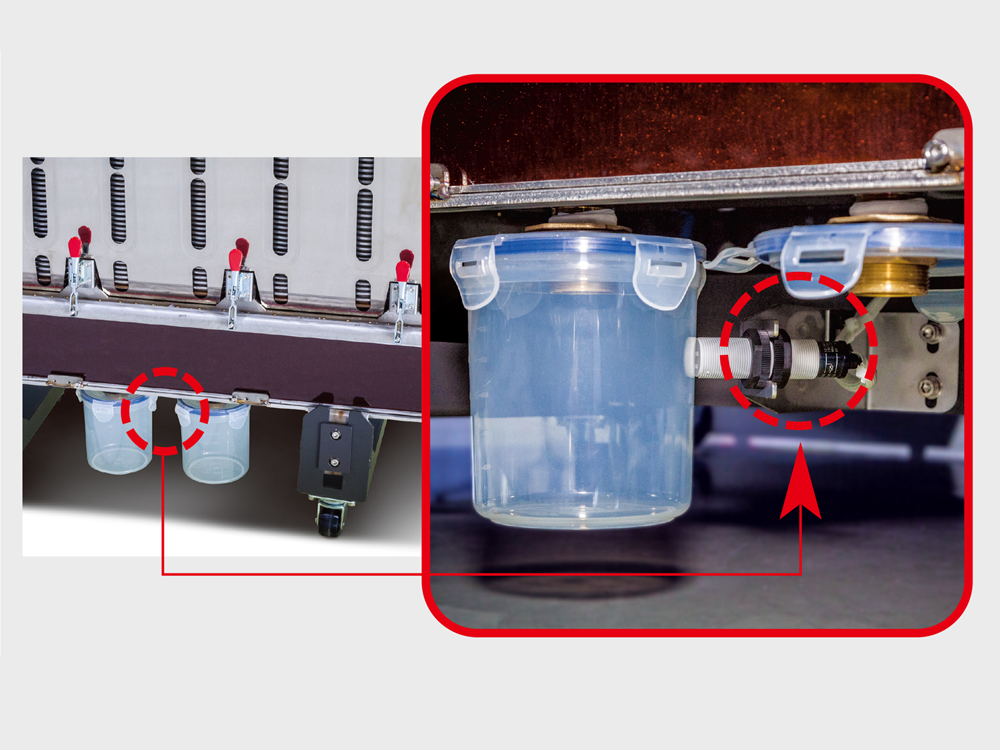

- One touch removable type 2 Way Radiator

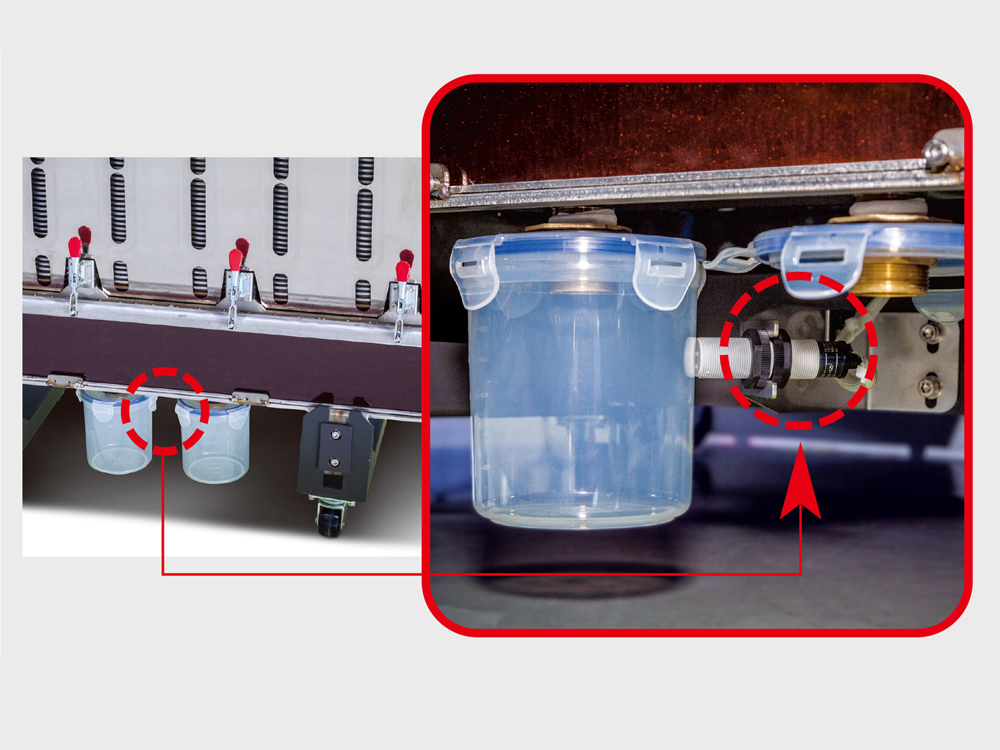

- Realized improvement of product quality through reduction of Flux inside of oven and collection rate of Flux due to additional installation of highly performed FMS, optimized the equipment in PH. Reduce downtime by applying one touch sliding removable type and level sensor of FMS's Flux contain. This sensor alarms when fill it up.

-

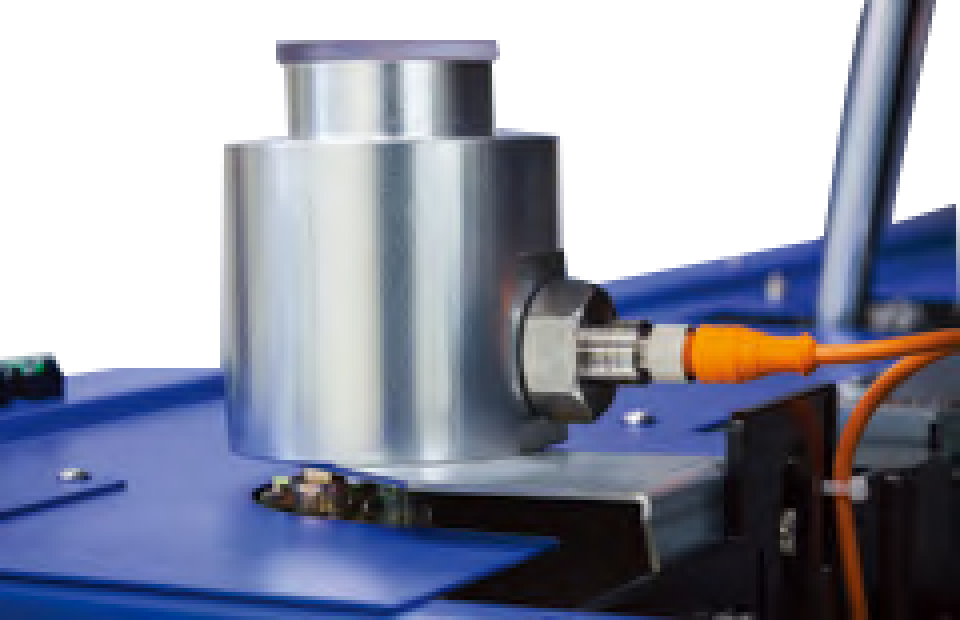

- Oil level detection sensor for C/V chain

- Sensing function of Conveyor Chain Oil Level alerts protection of C/V chain in case of shortage of oil with functions of alarm and message during operation.

-

- Flux level sensing Flux Drain Container

- Detect precise cleaning time of Flux through alarming and message on level of Flux, collection container of Flux Management

-

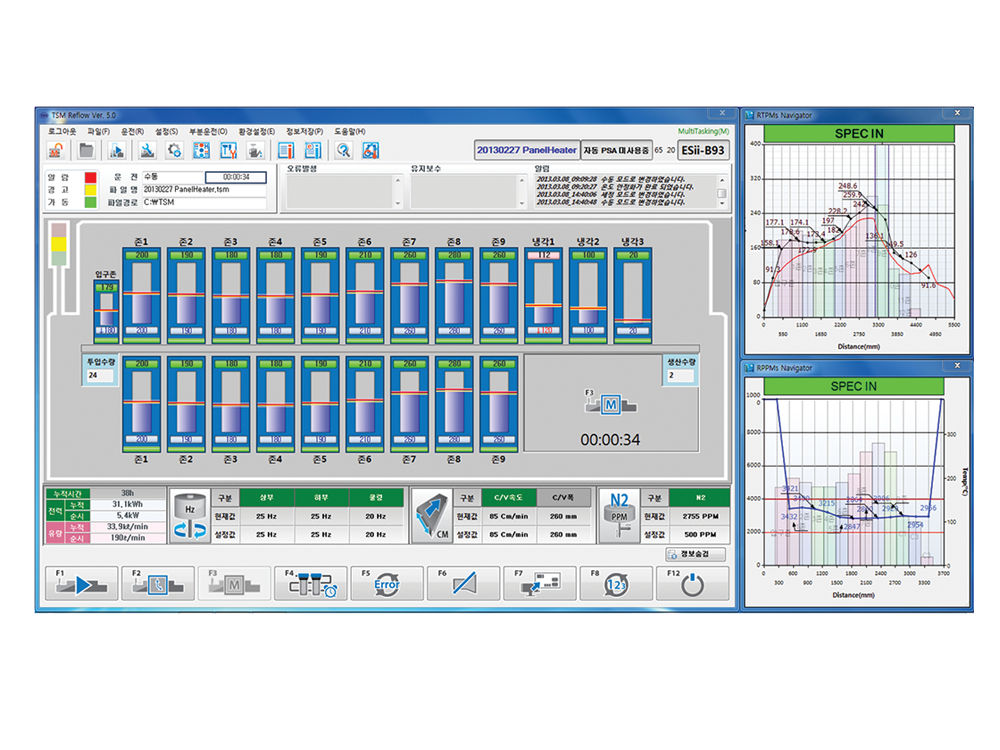

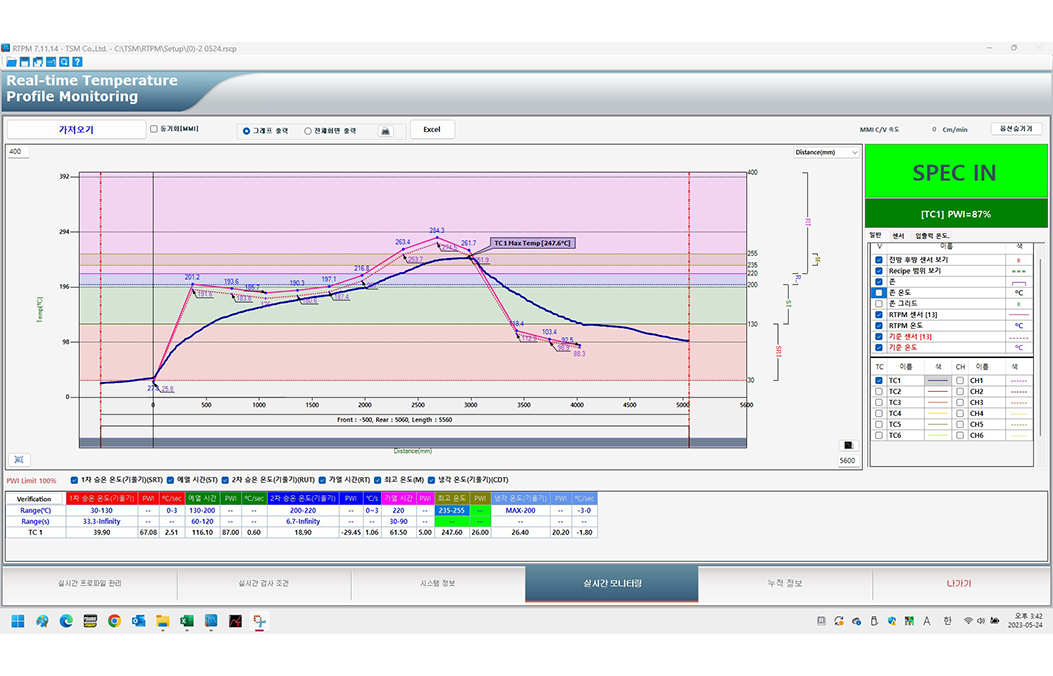

- RTPM (Real Time Temperature Profile Monitoring System)

- - Temperature Profile Memory Function per production and product type

- - No need on Profile Check when changes of production model

- - Real time saving of Reflow information (basic one minute in scale)

- - Able to checking temperature condition of Reflow with real time graph

- - Provide all information of Reflow through host computer communication

- - Interface TSM Reflow MMI Program

-

Ceaseless innovative TRN series for the best Reflow offers the utmost

customer

satisfaction with the outstanding models, aiming Econology and Humanism,

a core philosophy of TSM

-

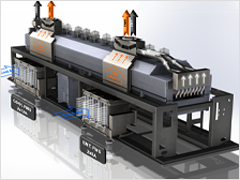

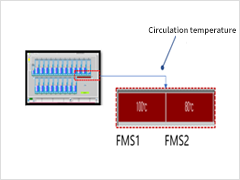

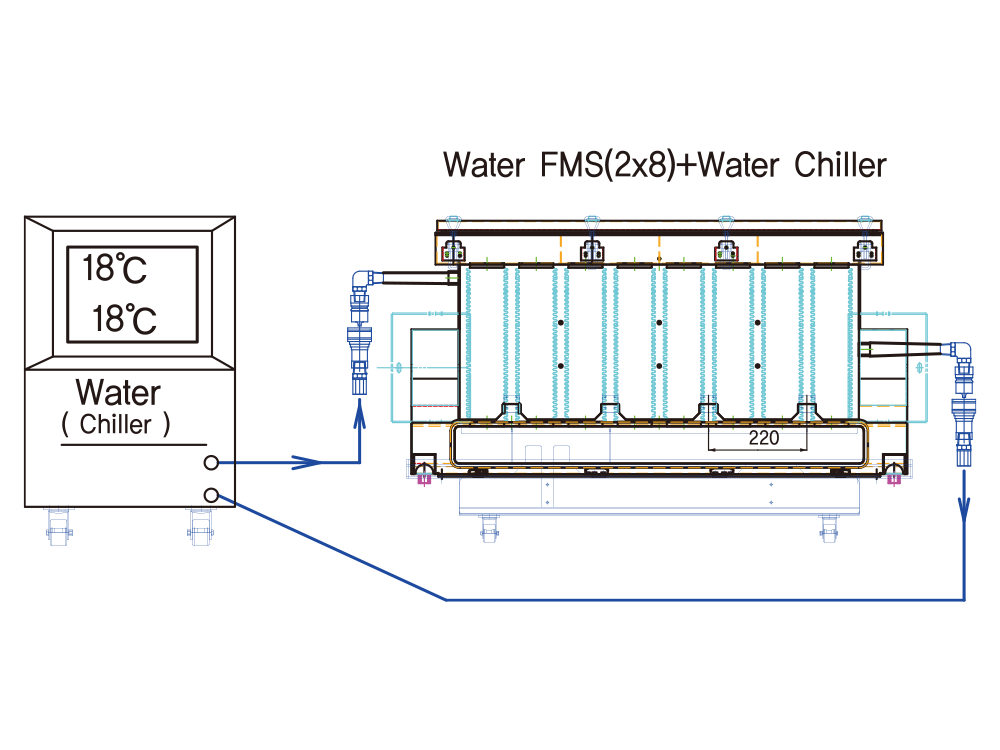

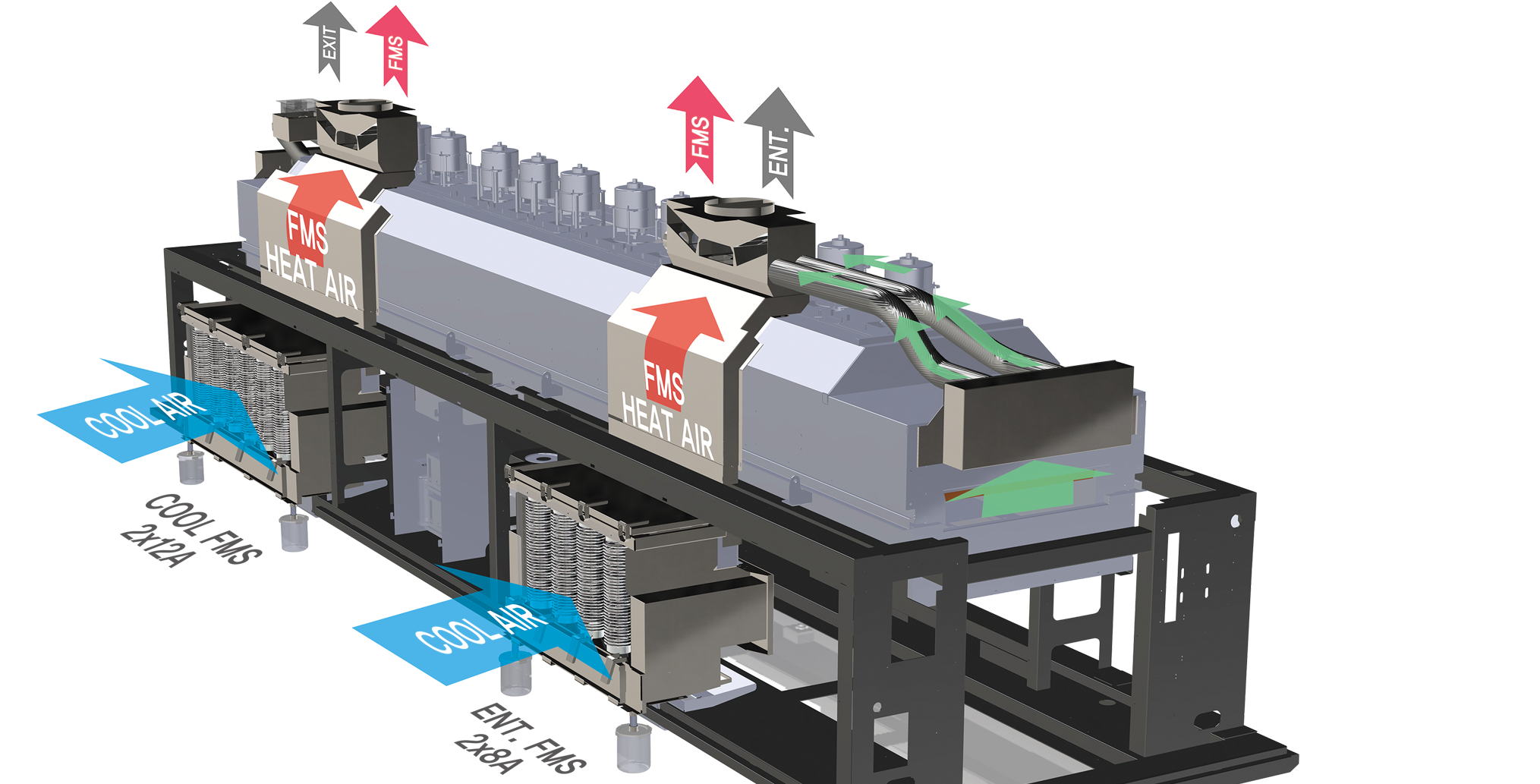

- NEW FMS, Heat Discharging System

-

Circulate the air in order to cluster Flux inside of oven and

exchange the heat continuously

Heat discharging system newly mounted realizes cost saving of its ventilation during process by emitting the heat through the way of closed duct.

-

-

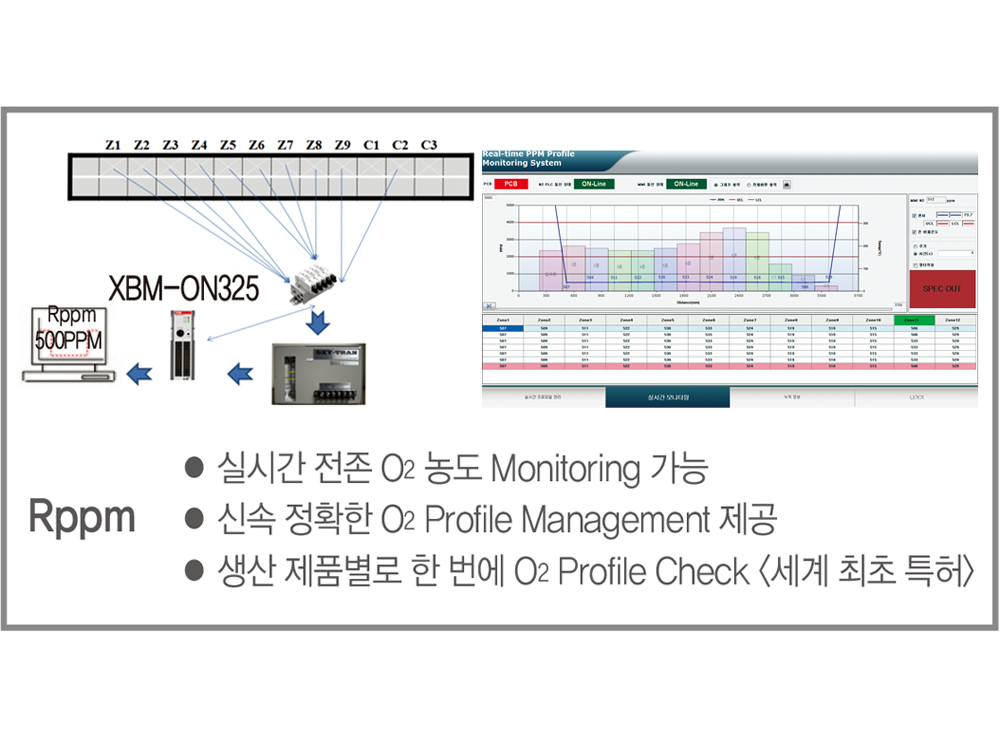

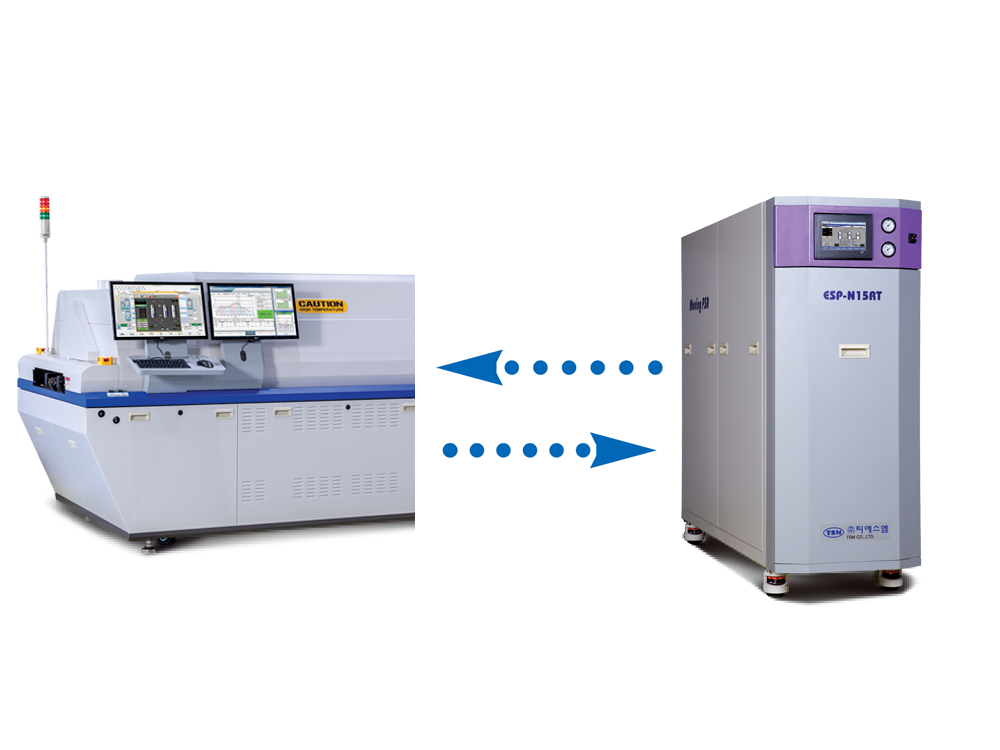

- RPPM (option)

-

Monitoring conditions of O2 ppm in all zone at all time, managing

O2 ppm Profile Graph Data

according to types of production products with time slot and Spec and producing quality products while maintaining even O2 ppm

-

-

- 2RADIATOR(option)

- Achieved double performance of collecting flux by applying additional FMS in zone of Pre Heating on top of FMS in cooling zone and also able to extend a period of FMS's PM.

-

N2 Reflow

TRN III-a Series

Constant innovation for the best Reflow!

TRN Series, the top-level model to realize Econology and Humanism,

pursued by TSM

Deliver our cutting-edge technology and best product performance

to our valuable customers all the time

Product Features

- · Realize Flux Zero in OVEN -> equip FMS applied with patent technology

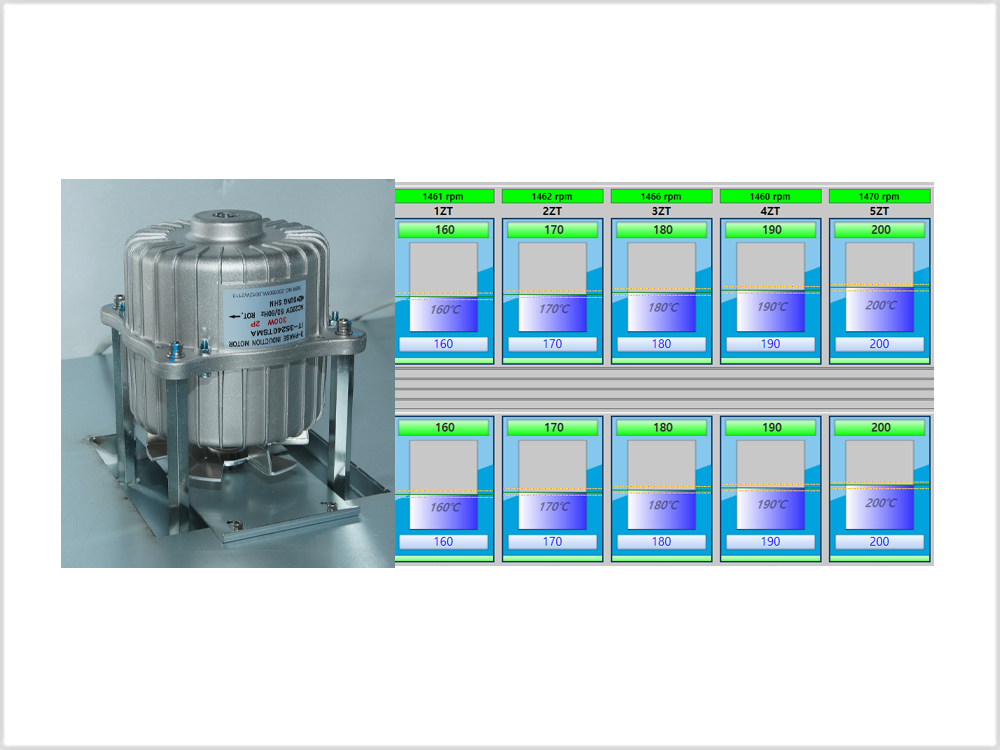

- · Thermal Interference Innovation in each zone -> Able to set up temperature difference with 60ºC in max. of interzone

- · Internal Heat Reduction of Reflow -> apply New Emission System

-

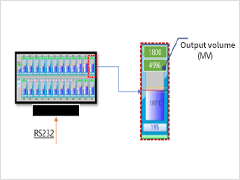

· Real-time Monitoring (optional)

- - Real-time Temperature Profile Monitoring (RTPM)

- - Real-time Oxygen Concentration Monitoring in each zone (RPPM)

- - Conveyor Vibration Monitoring

- - Monitoring a number of rotations of Blower Motor

- - Circulation Temperature Monitoring of FMS

- - Output Monitoring of Heater Control

- - Alert of Conveyor Chain Oil Level

- - Alert of Dust Collection Flux Level

- · Powerful performance of FMS ever before with double sized capacity of FMS installation (2x8=>2x12A)

- · Reduction of N₂ consumption with more than 20% compared to previous models (fan size / change of perforated plate)

- · Improved ppm performance with more than 30% compared to previous models (curtain shutter applied)