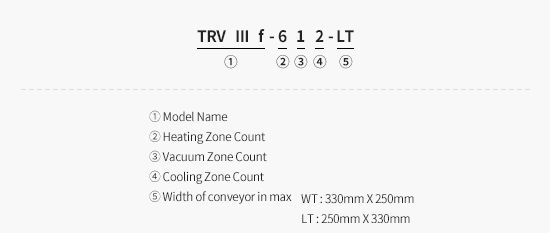

Twin Vacuum Reflow

Perfect solution to critical Tact Time of Vacuum Equipment

VACCUM REFLOW

TRV - SERIES

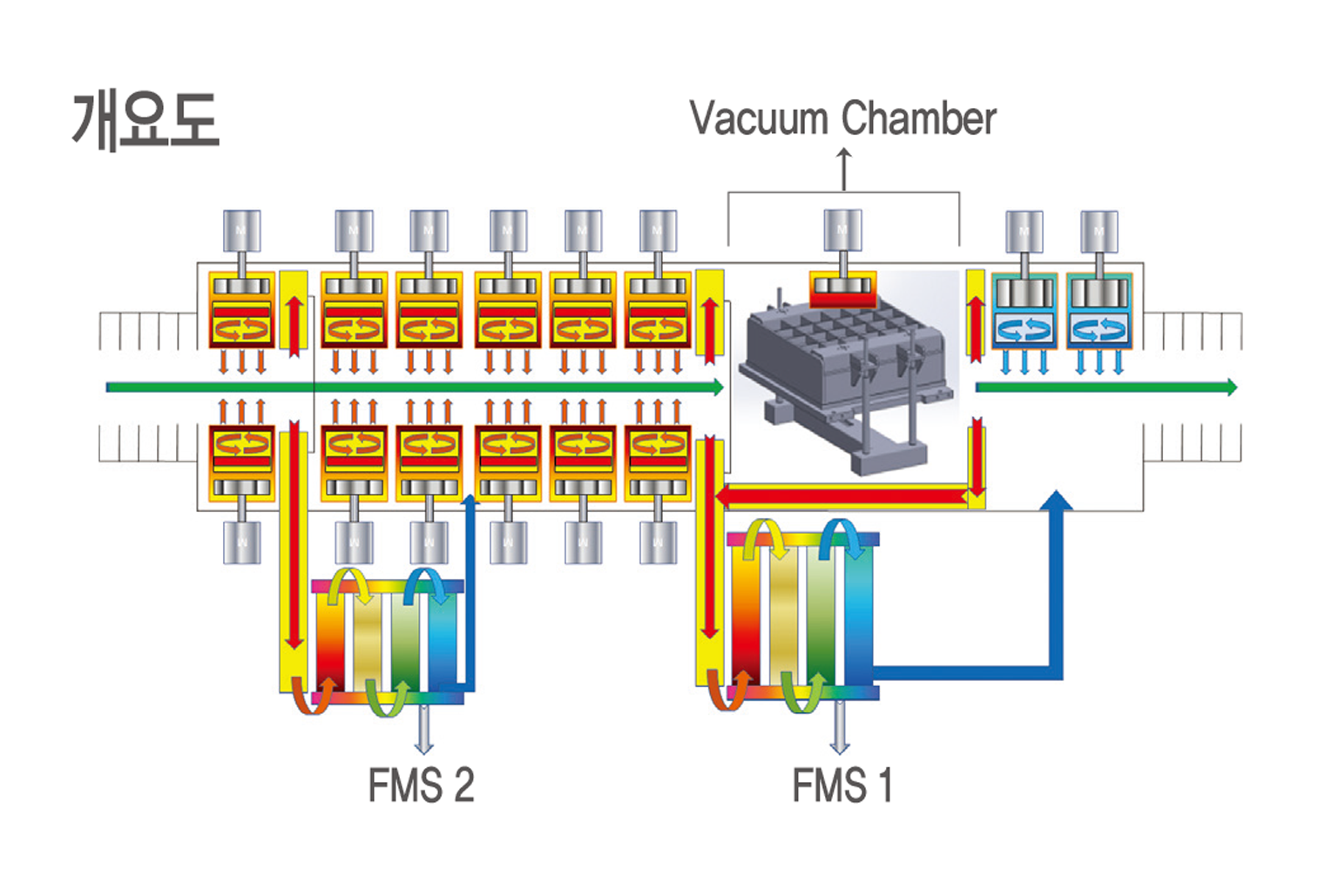

- Two Vacuum chamber + Two ovens, independent operation

- Reduction of production line space with compact design

- Independent system for each lane (temperature setting per lane, production available with one lane when one lane is PM)

-

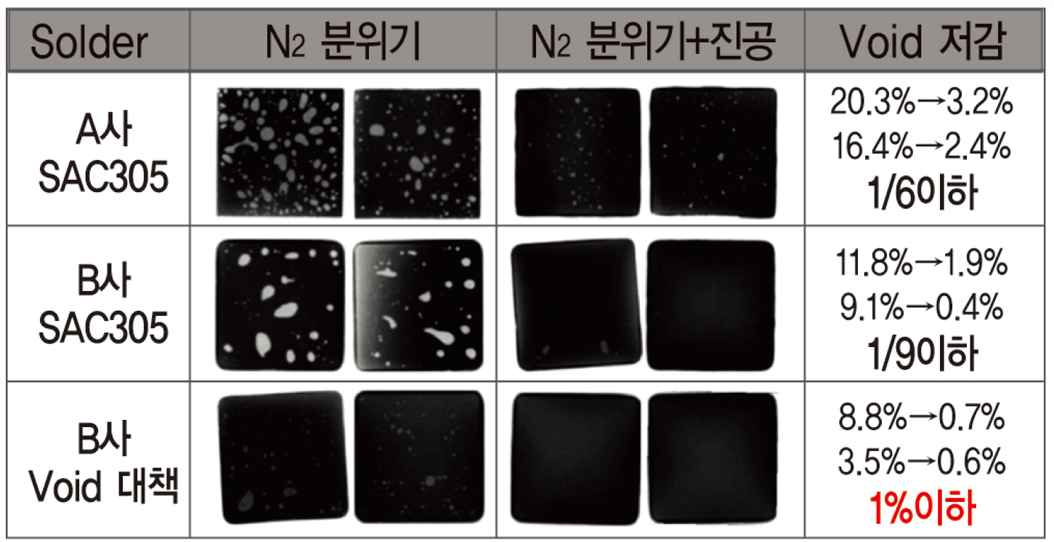

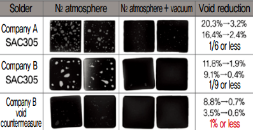

01. Effect of vacuum function

Combination of heating up heat wind circulation and vacuum reduces occurring Void despite of large space soldering.

-

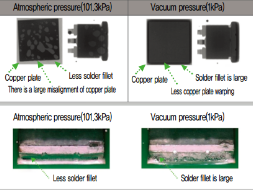

02. Effect of reduction of Void

Secure forming fine fillet with thin and event solder thanks to reduction of Void and effect of self alignment from swelling and twisting.

-

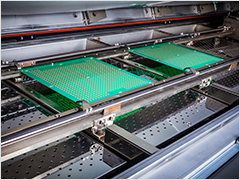

03. PCB transferring system optimized for in-line production

-

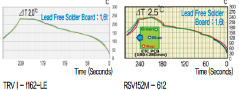

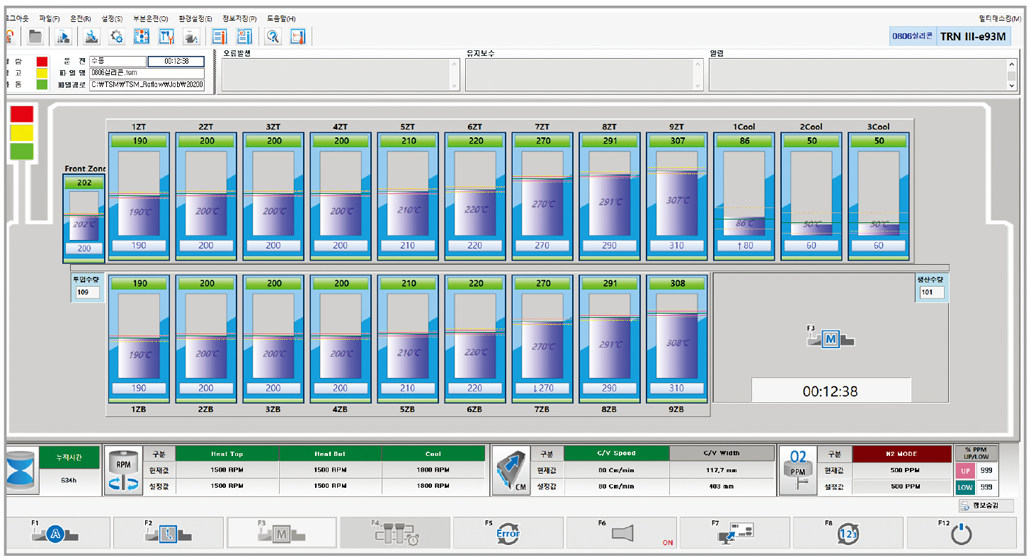

04. Heating performance

Secure high quality Soldering with even lower number of zone through combination of vacuum chamber and up / down heating circulation, improved for previous temperature profile condition.

-

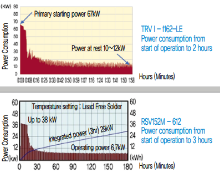

05. Ultra low power consumption

Realize ultra low power consumption through “RO” lightening main body and high insulation and saving of energy, CO2 and electricity cost.

-

06. High insulation specification

Combination of the low thermal conductivity, doubling insulation materials, resinification of insulation cover and ultra low power consumption of electricity enables dramatic reduction of energy and CO

-

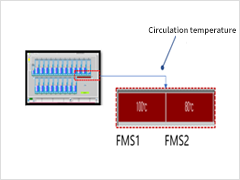

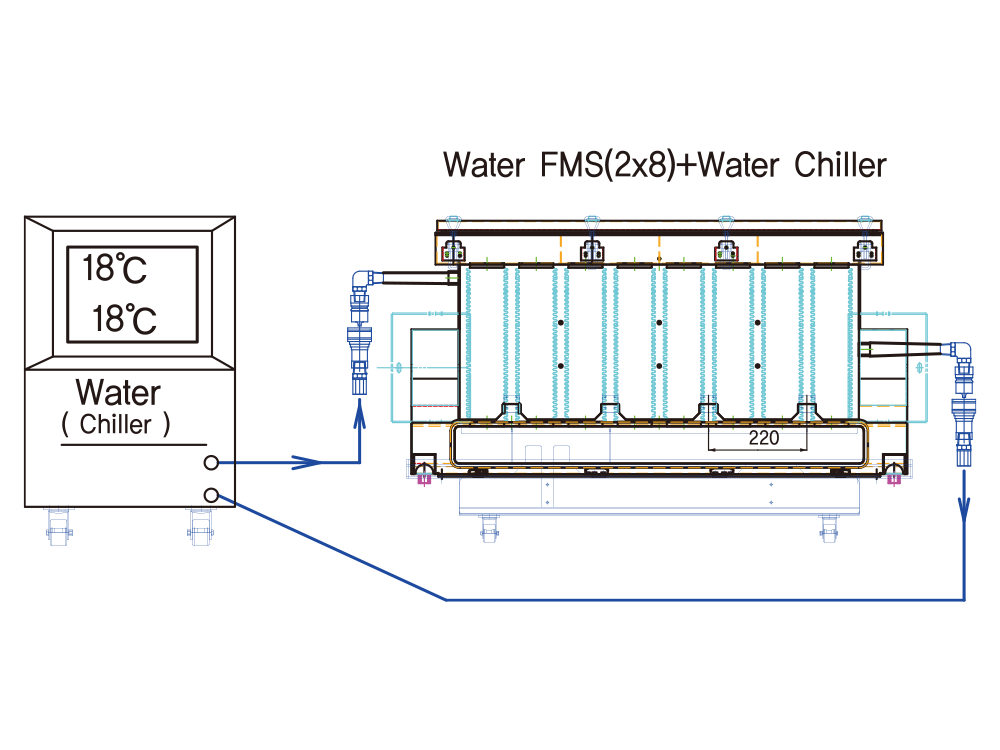

07. Collecting System of Flux (TSM)

TSM : Single Ass'y structure combined for each UNIT enables one touch separation, exchange and re operation; able to extend Flux PM period by applying 2FMS on recent equipment. ETC : Highly perform on collecting Flux thanks to deploying dust collection UNIT, respectively per preheating, heating and cooling process and easy access on cleaning with cleaning liquid due to separating filter each box.

-

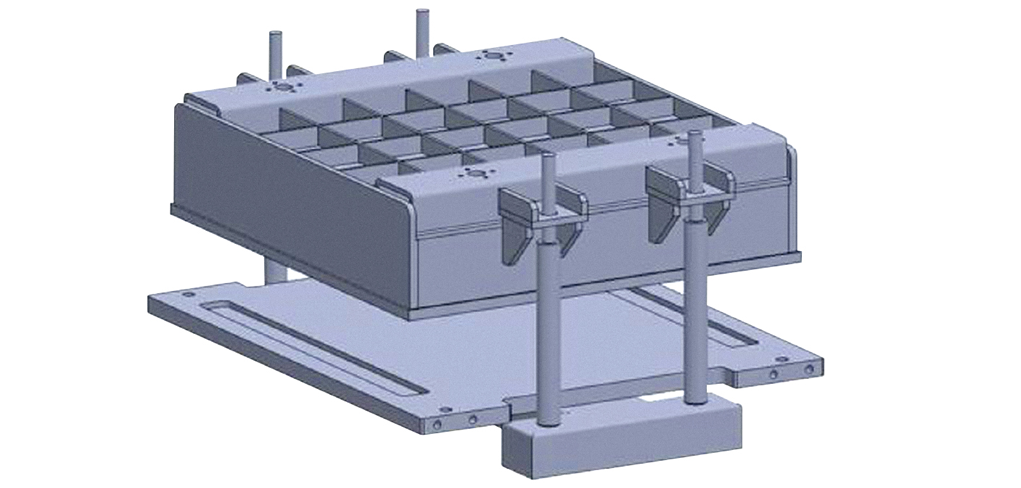

08. Vacuum Chamber

Effective degree of vacuum with complete close vacuum chamber enables to control and reduce Void effectively

-

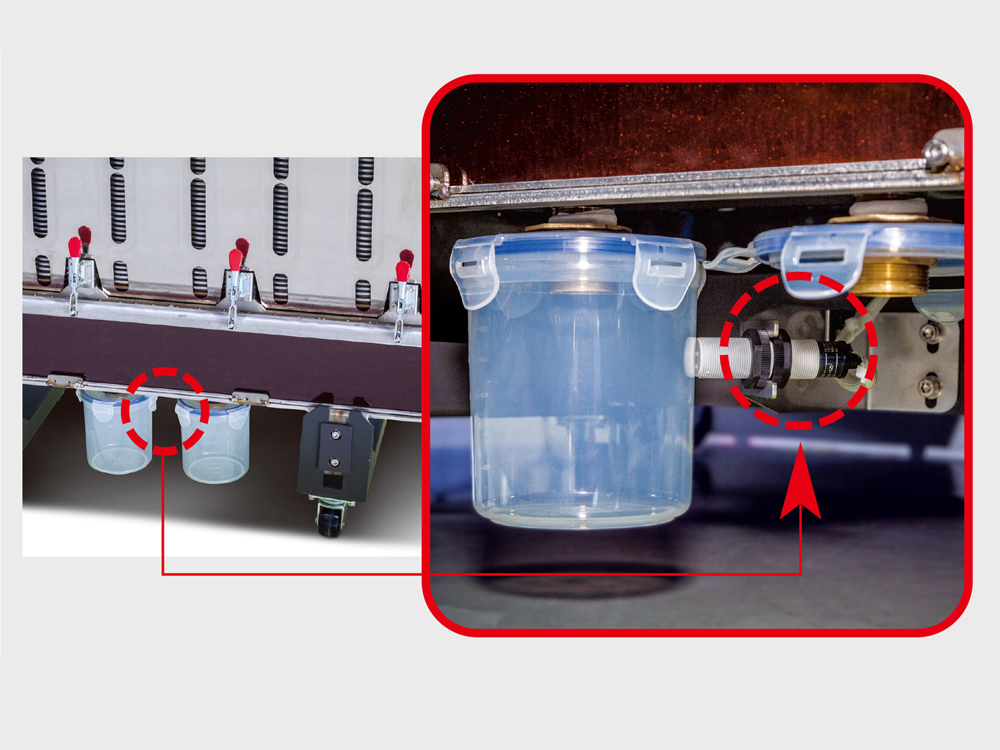

09. Filter Unit

Protect Flux contamination of Vacuum Pump through multi-staged filters and realize simple cleanin.

-

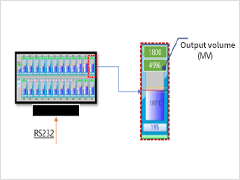

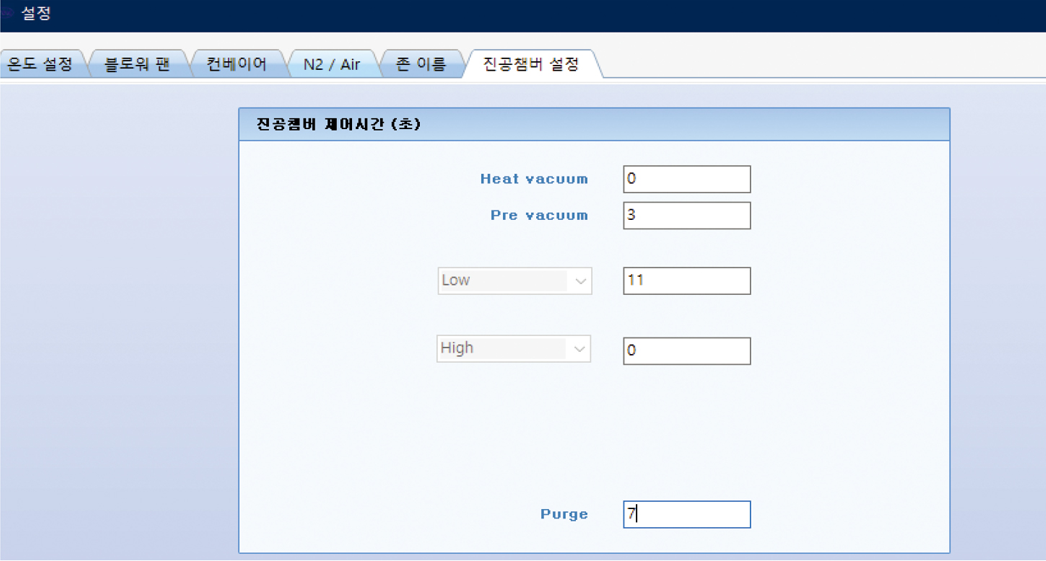

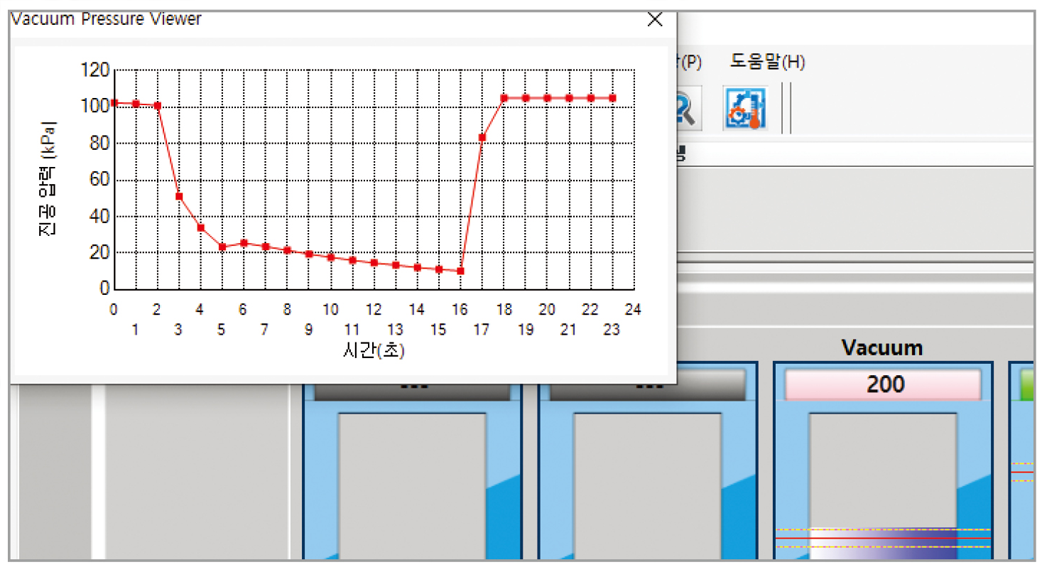

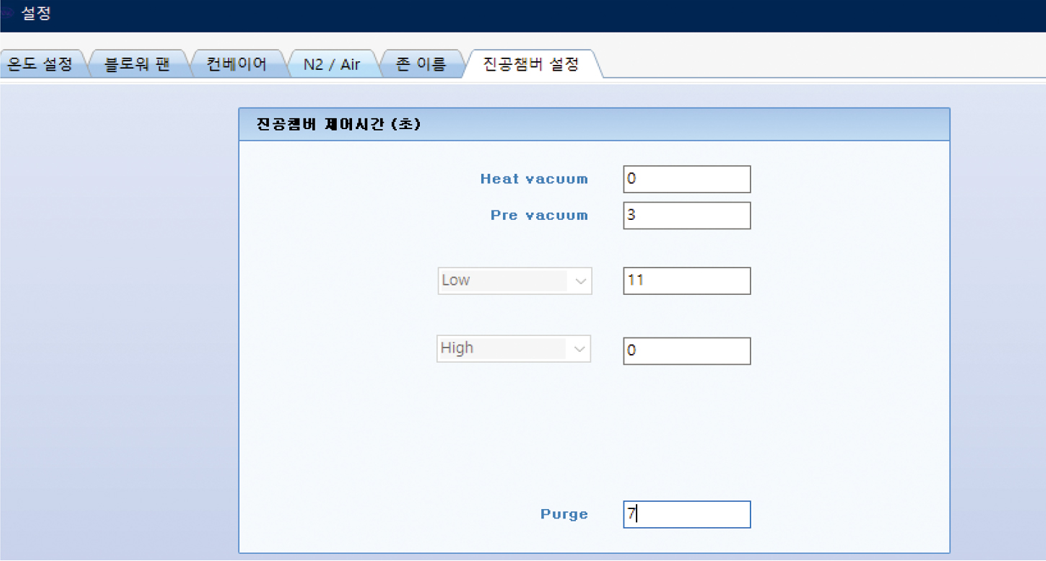

10. Controlling degree of a vacuum with three stage

Flexibly handling control of degree of a vacuum with multi stage control according to characteristics of product.

-

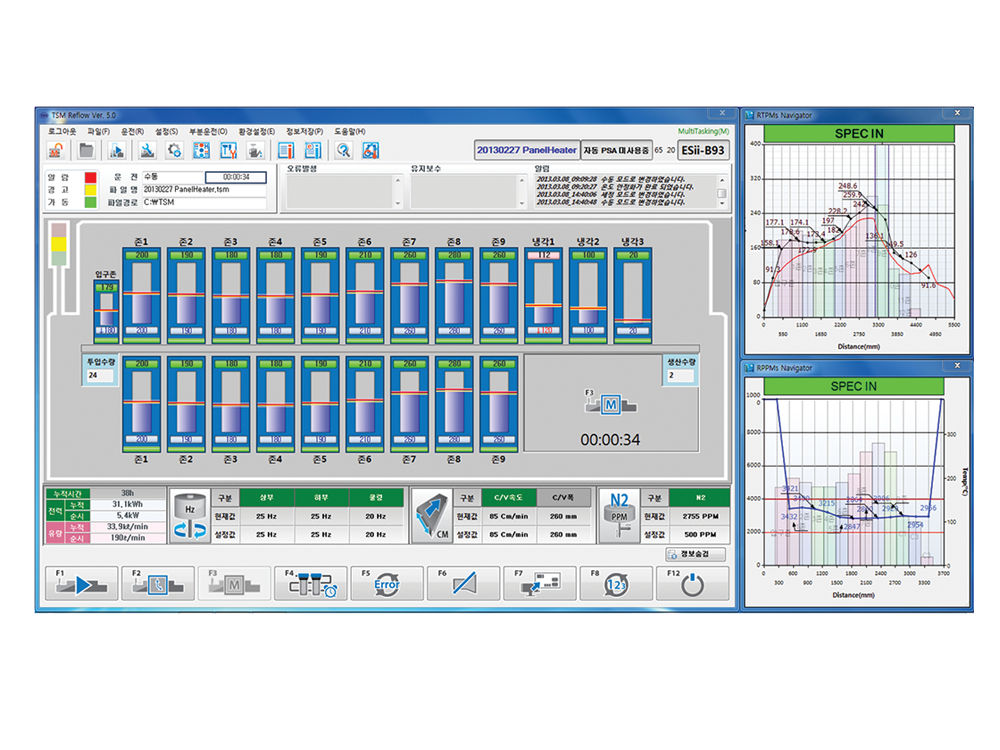

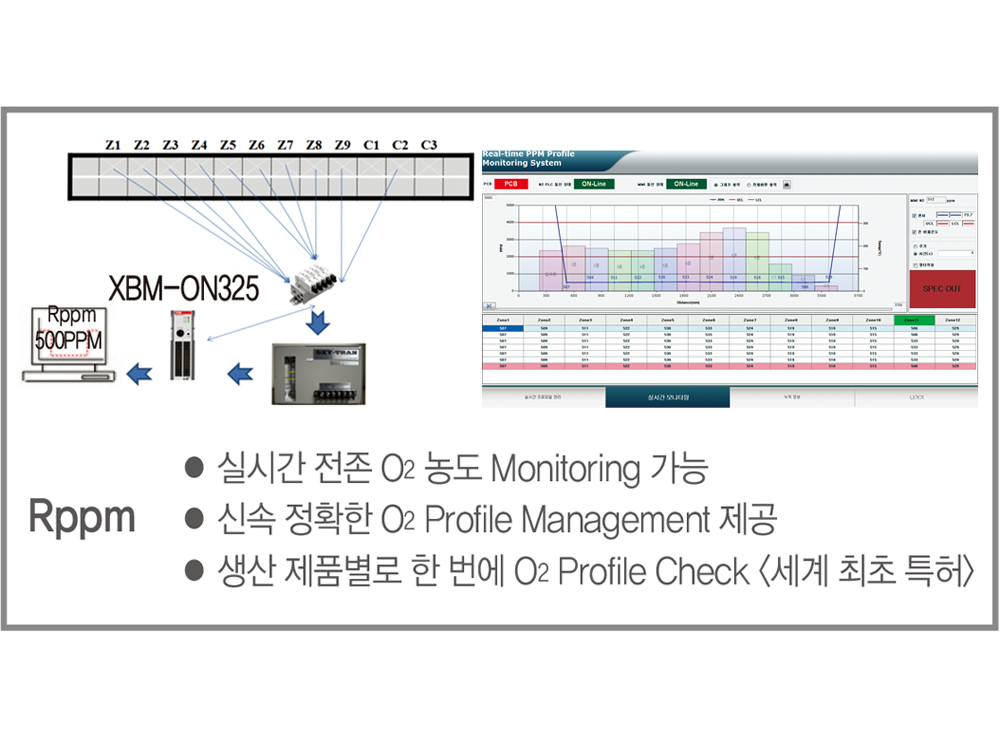

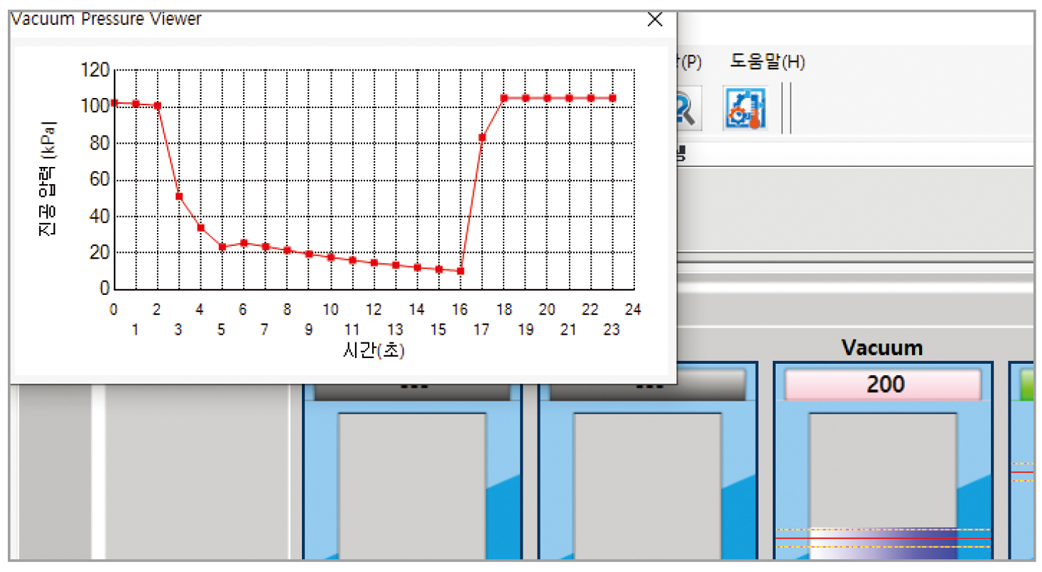

11. MMI realization function of degree of a vacuum graph (Option)

Able to monitor degree of a vacuum with its graph on MMI monitor.

-

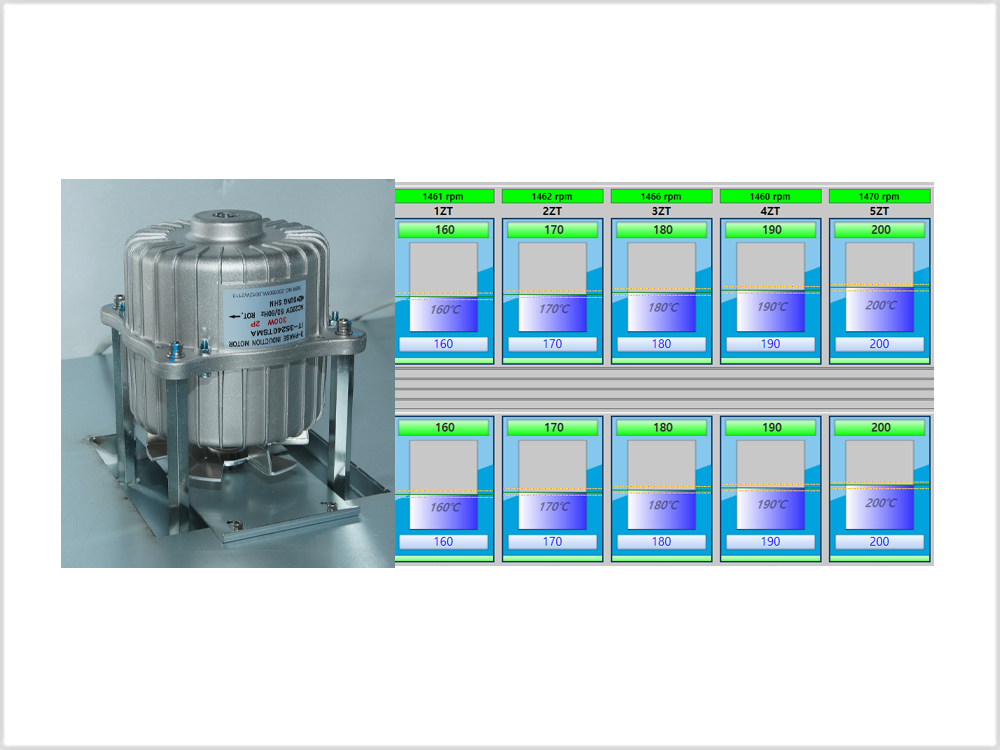

12. RPMS: indicating a number of spinning MMI function for all zone B/M rpm (Option)

Visualize a number of spinning blower motor fans in real time. Alert with alarm if out of setting order caused by an error of its motor.

사양 / Specifications

| Name of Models | TRVⅠ- f612-WD | TRVⅠ- f612-LE | TRVⅢ- a612WT | TRVⅢ- a612LT |

|---|---|---|---|---|

| Heating (zone) 6 | 6 | |||

| Vacuum (zone) | 1 | |||

| Cooling (zone) | 2 | |||

| Voltage | 3Ø 380V | |||

| Heating temperature | Max 350 °C | |||

| Degree of vacuum | 1~10 kPa | |||

| Consumption capacity of nitrogen | 300~400ℓ/min | |||

| Outer length | 5,406mm | 6,286mm | 5,406mm | 6,286mm |

| Name of Models | TRVⅠ- f612-WD | TRVⅠ- f612-LE | TRVⅢ- a612WT | TRVⅢ- a612LT |

|---|---|---|---|---|

| Outer width | 6 | 2,525mm | 2,365mm | |

| Outer height | 1,550mm | |||

| Height of passing parts | Upper 30mm / Lower 30mm | |||

| Width of control panel | 100~250mm | 100~330mm | 100~250mm | 100~330mm |

| Length of control panel | 100~250mm | 100~330mm | 100~250mm | 100~330mm |

| Height of remand | 900~920mm (STD 900mm) | |||

| Collection of Flux | 표준 장착 (2 FMS) | |||

| Option | Roller 부착 레일 / 대형 사이즈 챔버 / 3Ø 380V 외 전압 | |||

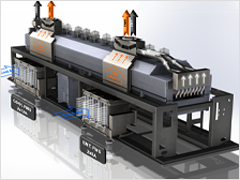

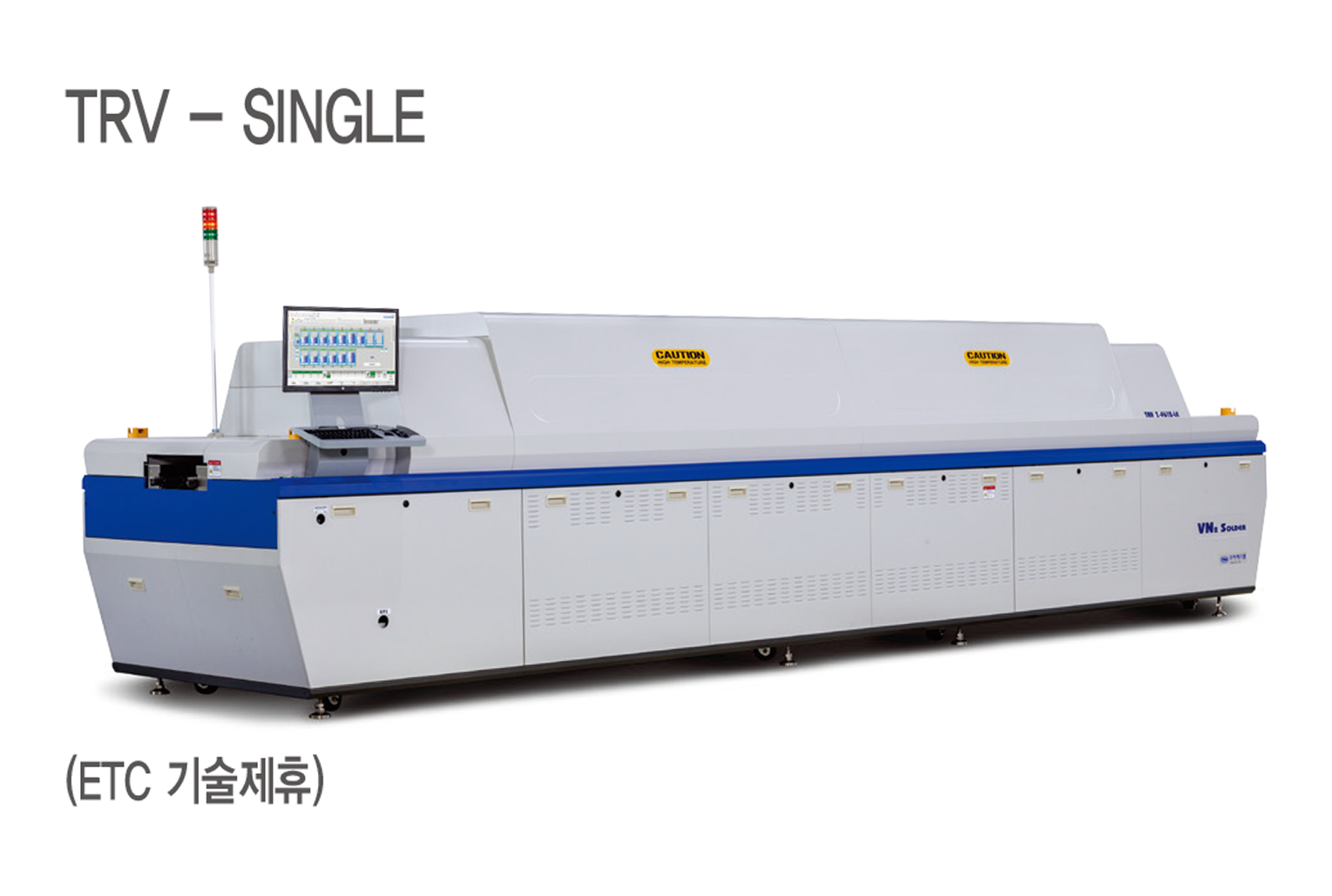

TRV III-a Series

Don’t worry Tact Time of Vacuum Reflow anymore!

Secure overall Productivity Balance with TSM’s

Twin Vacuum Reflow in Line by realizing level

of Tact Time equivalent to other Reflows

Product features

- · Independent Twin Vacuum Reflow as the World Premier (2X Vacuum Chamber + 2X Oven + 2X PC independent operation)

- · Doubled productivity compared to Single Reflow

- · World’s best tract time (min. 15 sec /PCB)

- · Optimized to mass production line

- · Basic application of TRV I-f model’s specifications

- · Completely vacuumable dedicated compression chamber of TSM’s vacuum Reflow

- · Transport System without jamming PCB (ETC Technical Partnership)

- · Minimize the gab of in/out conveyor to prevent PCB Drop

- · Enhanced durability with none conveyor driven roller in high temperature sections

- · Able to correspond with embedded small sized vacuum pump, minimized for vacuum chamber

- · Easy control of vacuum level and reduction of vacuum time

- · Vacuum Profile Monitoring System

- · Apply 2 FMS to maximize Flux Collection