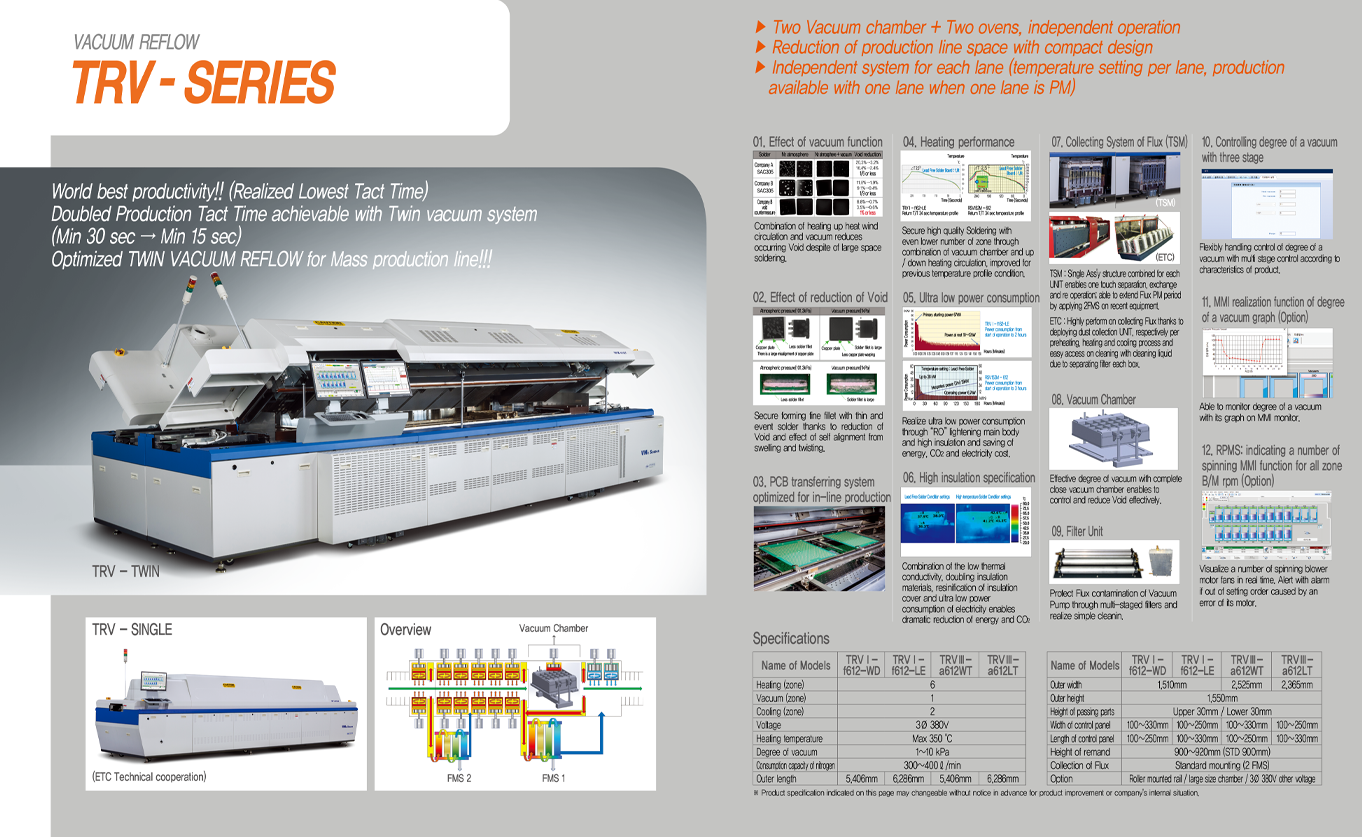

Twin Vacuum Reflow

Perfect solution to critical Tact Time of Vacuum Equipment

Twin Vacuum Reflow

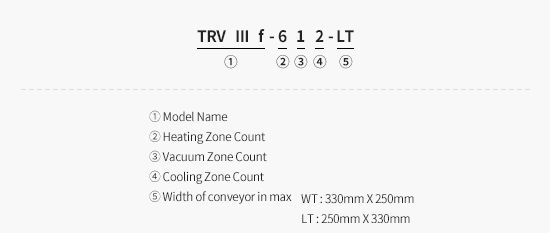

TRV III-a Series

Don’t worry Tact Time of Vacuum Reflow anymore!

Secure overall Productivity Balance with TSM’s

Twin Vacuum Reflow in Line by realizing level

of Tact Time equivalent to other Reflows

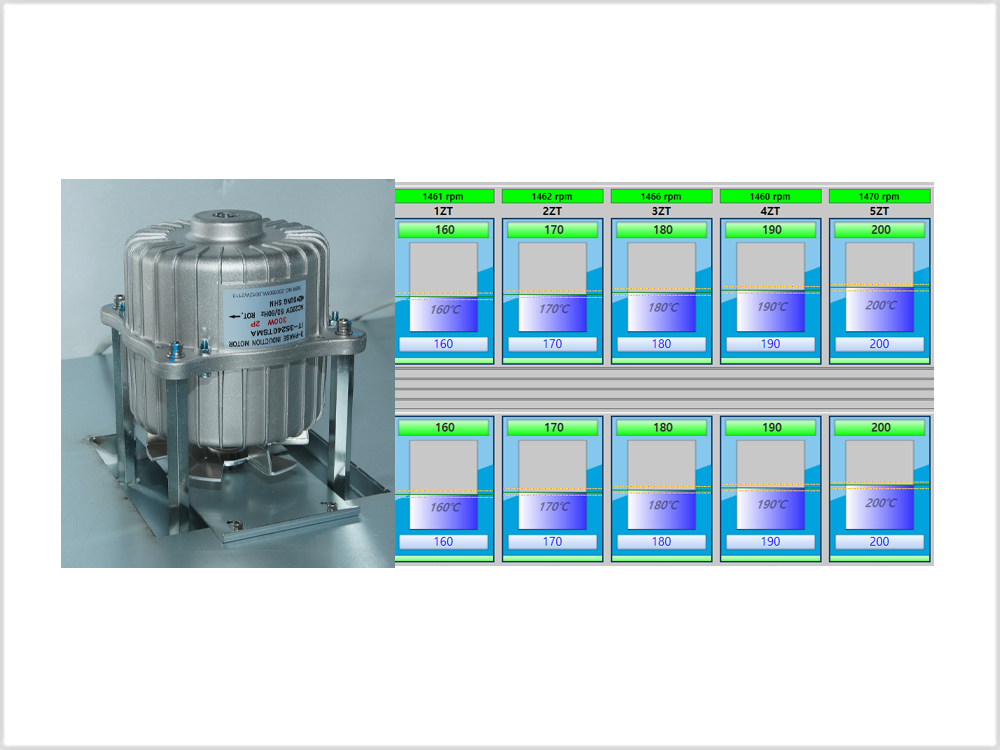

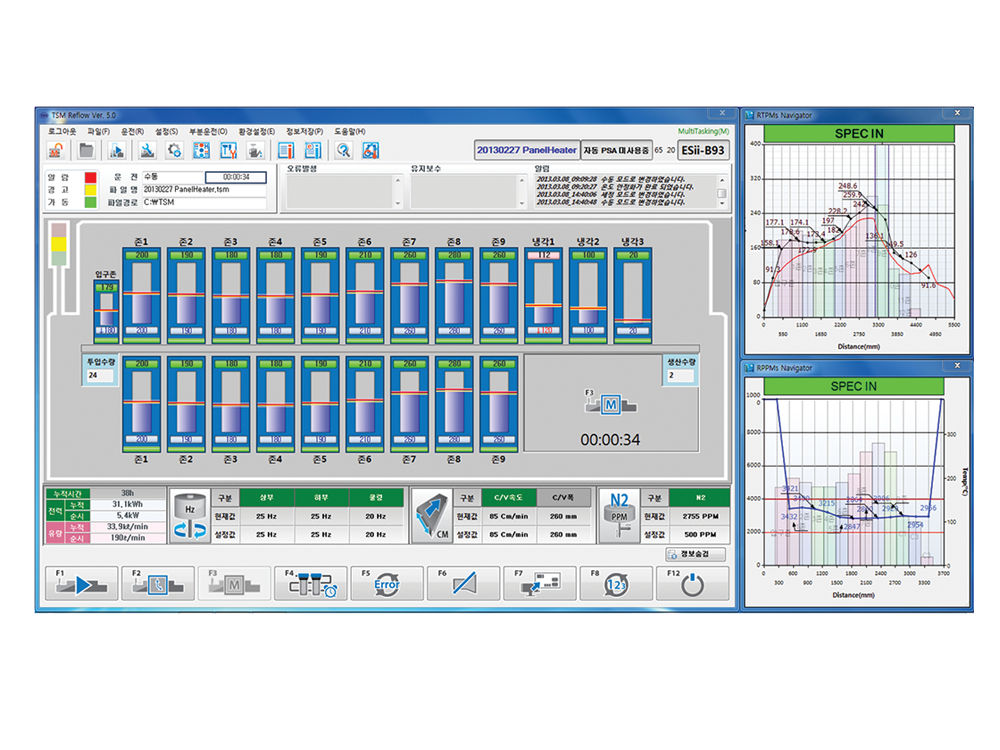

Product features

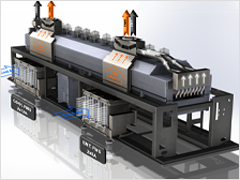

- · Independent Twin Vacuum Reflow as the World Premier (2X Vacuum Chamber + 2X Oven + 2X PC independent operation)

- · Doubled productivity compared to Single Reflow

- · World’s best tract time (min. 15 sec /PCB)

- · Optimized to mass production line

- · Basic application of TRV I-f model’s specifications

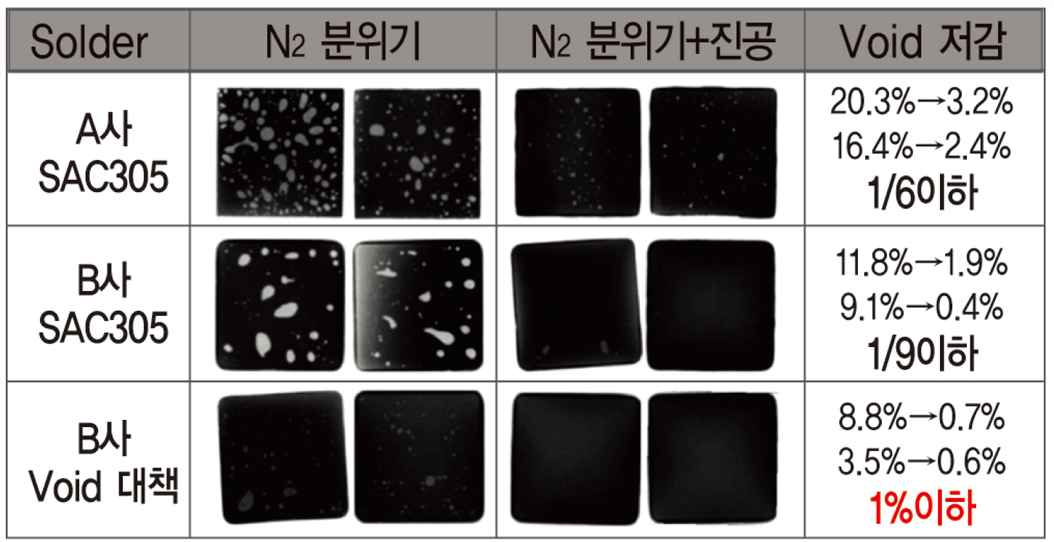

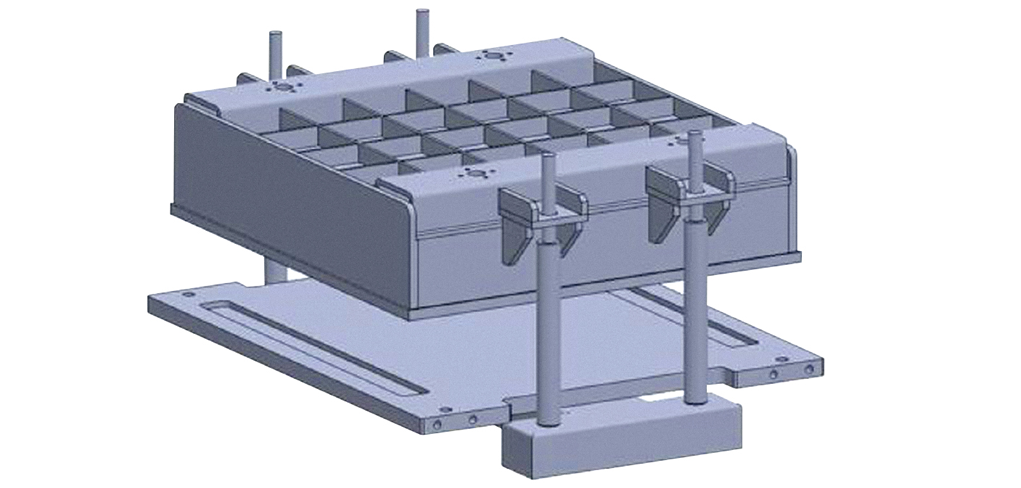

- · Completely vacuumable dedicated compression chamber of TSM’s vacuum Reflow

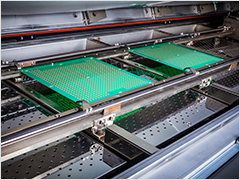

- · Transport System without jamming PCB (ETC Technical Partnership)

- · Minimize the gab of in/out conveyor to prevent PCB Drop

- · Enhanced durability with none conveyor driven roller in high temperature sections

- · Able to correspond with embedded small sized vacuum pump, minimized for vacuum chamber

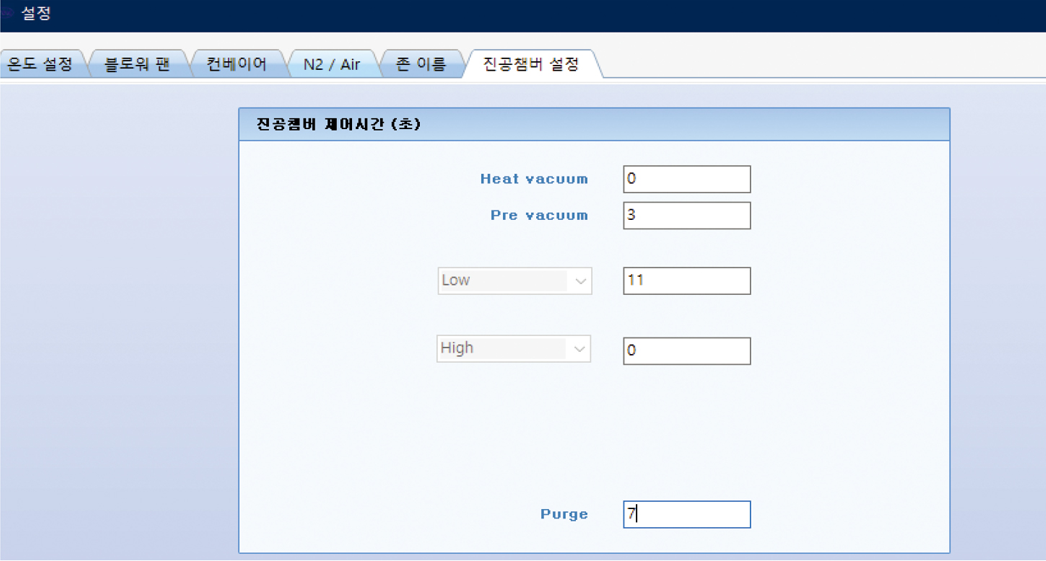

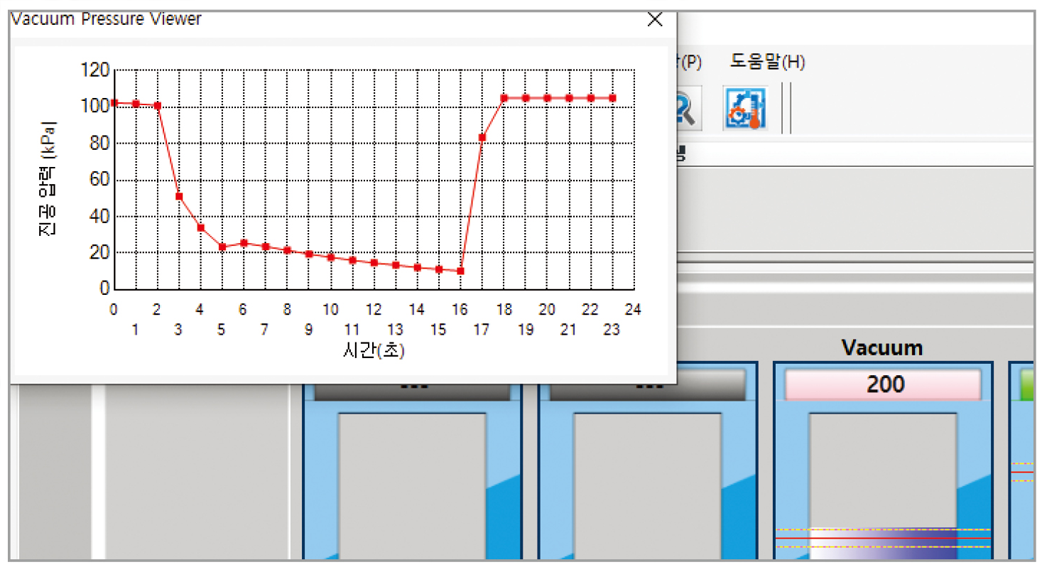

- · Easy control of vacuum level and reduction of vacuum time

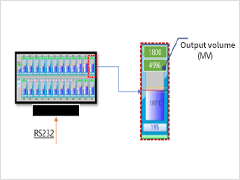

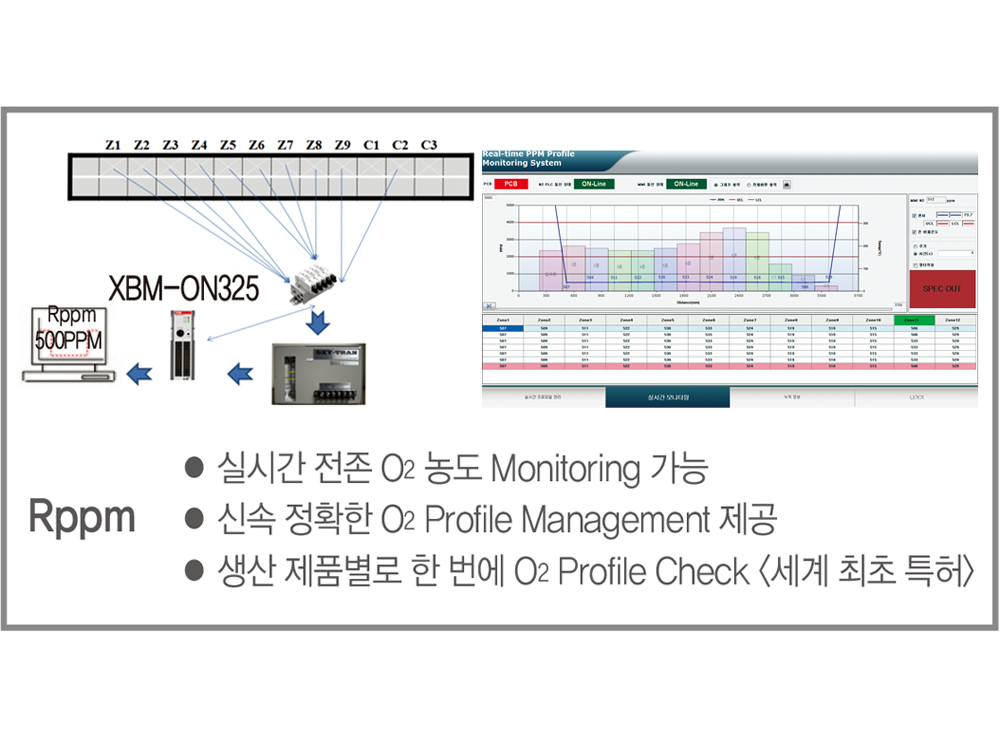

- · Vacuum Profile Monitoring System

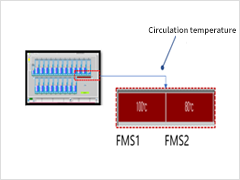

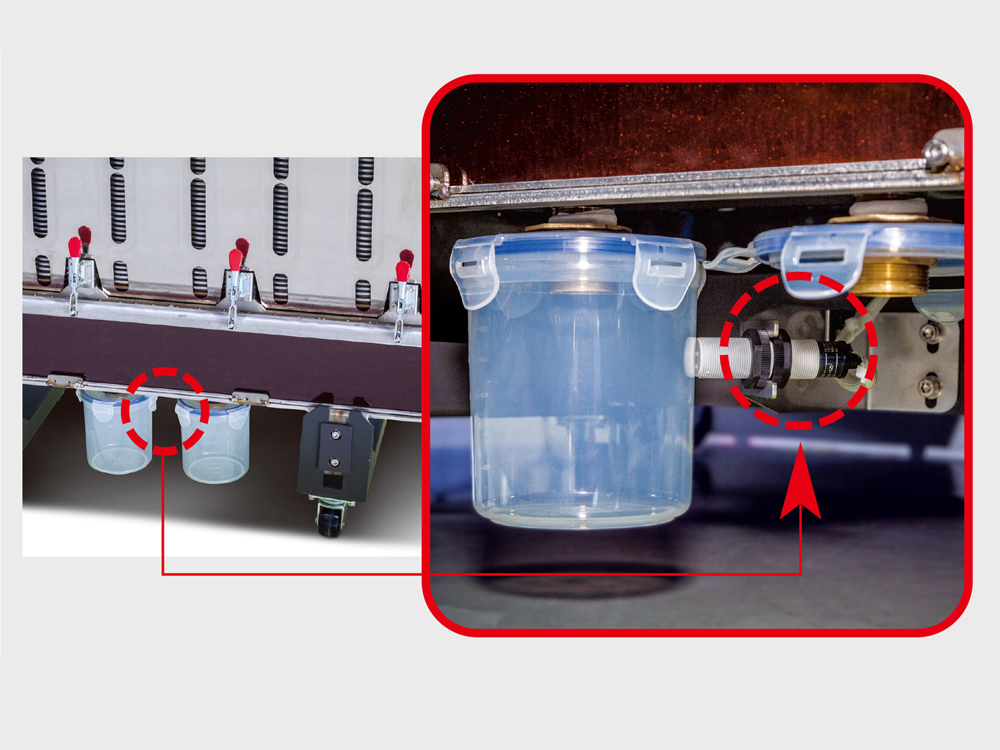

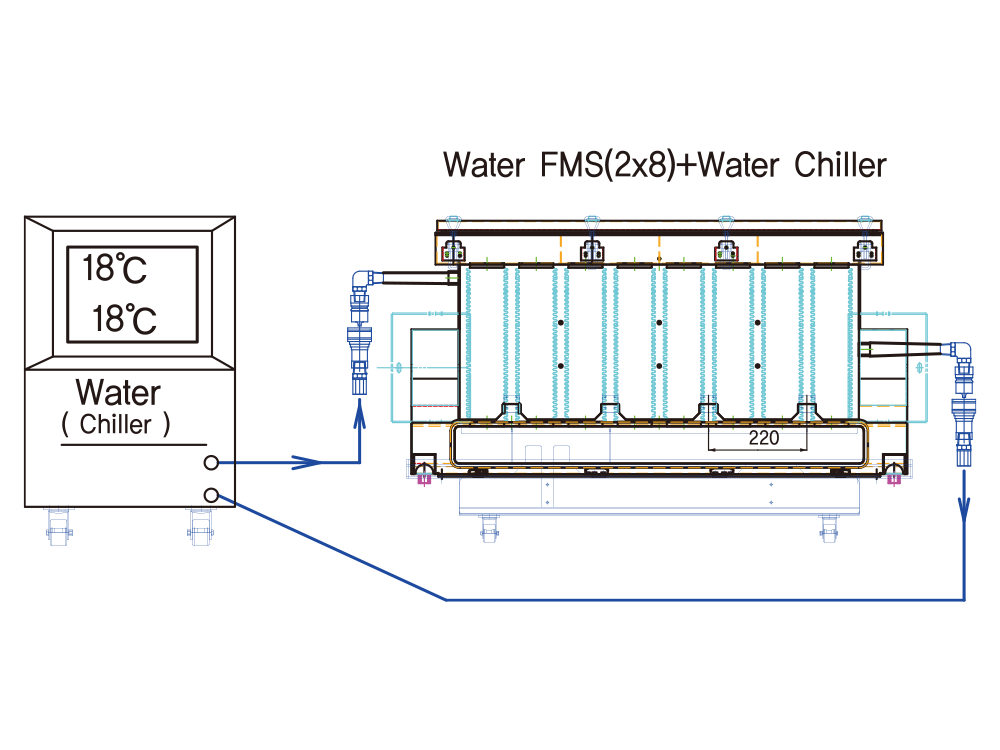

- · Apply 2 FMS to maximize Flux Collection